Keywords: Scaffold machine, Plank Deck Rolling Forming Machine, Rolling Forming Machine

Description: Metal Scaffold Plank Deck Rolling Forming Machine is designed to make many sizes of scaffold plank decking panels in batch and fully autoamtic.

Metal Scaffold Plank Deck Rolling Forming Machine

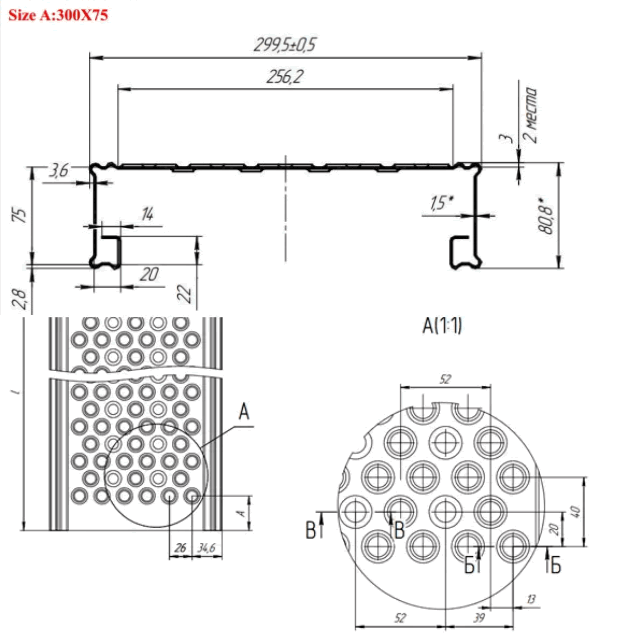

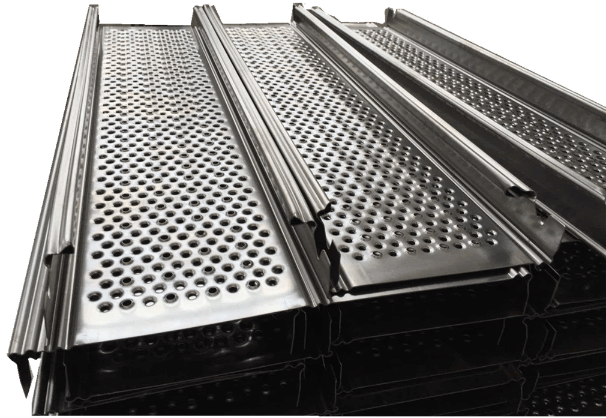

Metal Scaffold Plank Deck Rolling Forming Machine is designed to make many sizes of scaffold plank decking panels in batch and fully autoamtic. The whole production line is controlled by PLC, through PLC you can conotrol metal scaffold plank decking working speed, production quantity and also the length. Scaffold Metal Decks and Steel Planks are made in Galvanized and Painted with Plain Ends and Hook-on for Scaffolding System, Pipe and Fitting Scaffolding, the material thickness is from 0.8 to 1.5mm. In the market, there are lots of metal decking types, take the following profiles for example:

When using of the metal decking:

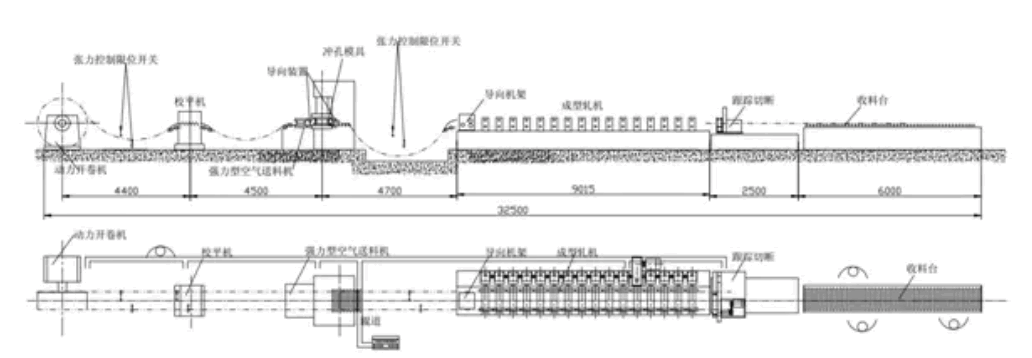

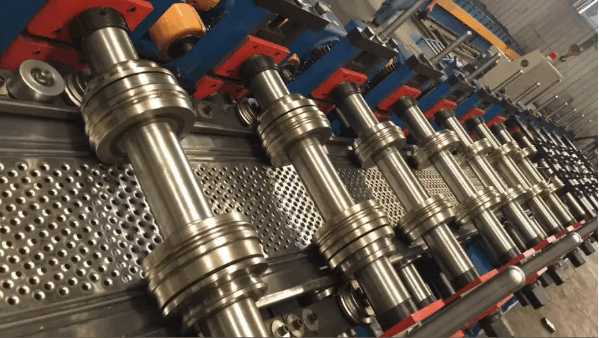

Metal Scaffold Plank Deck Rolling Forming Machine is designed like the following:

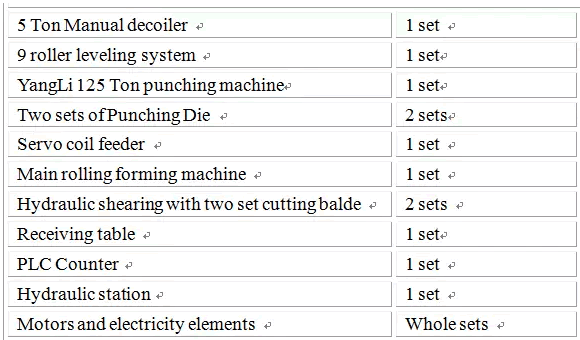

Metal Scaffold Plank Deck Rolling Forming Machine is composed by the fllowing elements:

Passsive decoiler, leveling machine, servo coil feeder, punching machinne, roll forming machine, hydraulic System, shearing system, runout table, and PLC control system.

Machine working process:

Decoiler–>leveling–>servo coil feeding–>punching system–>roll forming machine–>sizing and shearing System–> runout table

Machine working area requirements:

Area needed: 35×3.0×5 meter long.

Machine working direction: from left to right

Machine electricity: 380, 50Hz,3 phrase or customize, please tell in advance

Hydraulic oil: 46# oil

Gear oil: 18 # hyperbolic gear oil

PLC CONTROL SYSTEM of metal decking system:

The PLC control system, touch screen interface. The operator through the procedures for setting the automatic operation (programmable control and process control monitoring and Implementation for the

operator to control production line and modify the control parameters, and real-time monitoring the running state of the equipment, operation parameters and fault indication etc.. Part length digital setting, the length of the workpiece can be adjusted. Real time monitoring equipment

Operation status and fault indication.Operation mode has two kinds of manual / automatic. With manual, automatic switching function: in manual mode, single operation, convenient maintenance; in the automatic mode, the entire production run, startup sequence; across the board with emergency stop button, easy to handle emergencies to ensure equipment and the safety of the operator.

Here is the metal decking Youtube video link for your reference:

https://youtu.be/-S-TNqYfiQ8

More details pictures of the metal decking machine:

For this machine, if you need to know more information, please contact us at any time.

For this machine, if you need to know more information, please contact us at any time.