Ttile: Gearbox transmission metal roofing sheet rolling forming machine for Algeria

Keywords: metal roofing sheet machine, rolling forming machine

Description: Gearbox transmission metal roofing sheet rolling forming machine for Algeria is designed to handle the thickness around 0.8 to 1.2mm metal roofing sheet in batch fully automatically.

Gearbox transmission metal roofing sheet forming machine for Algeria

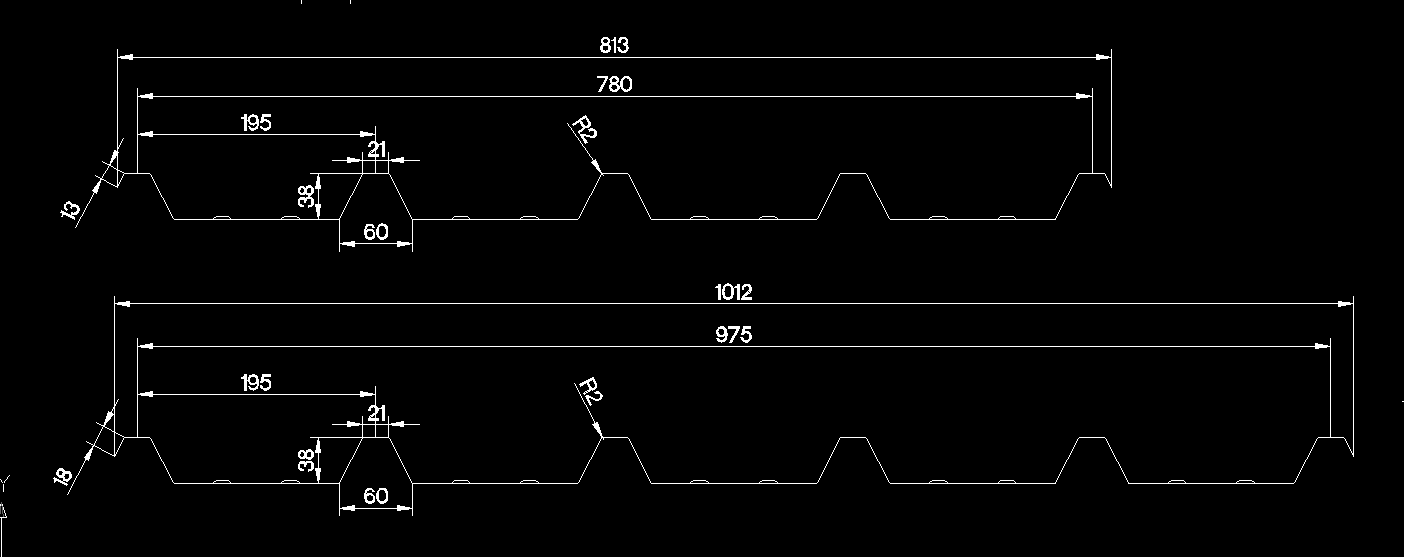

Gearbox transmission metal roofing sheet rolling forming machine for Algeria is designed to handle the thickness around 0.8 to 1.2mm metal roofing sheet in batch fully automatically. Different with other market, mostly the Algeria requires thickness of the metal sheet to 1.2mm, so we design the machine using the gearbox as transmission. And the machine working speed can reach 35 meter per minutes. Take the popular drawing profile in Algeria for example to show you how the machine is designed.

By one Gearbox transmission metal roofing sheet forming machine for Algeria it can both make those two profiles by adjust the input coil width handrails.

Gearbox transmission metal roofing sheet forming machine for Algeria features:

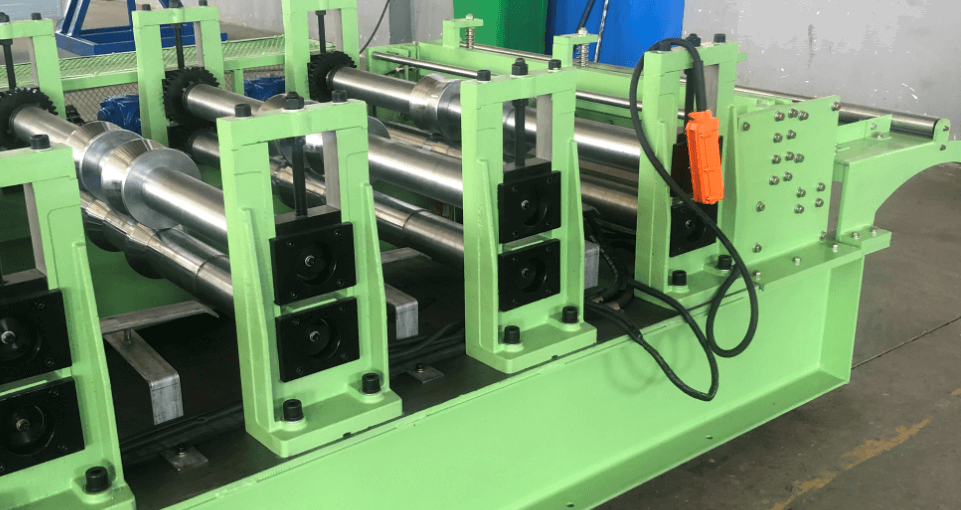

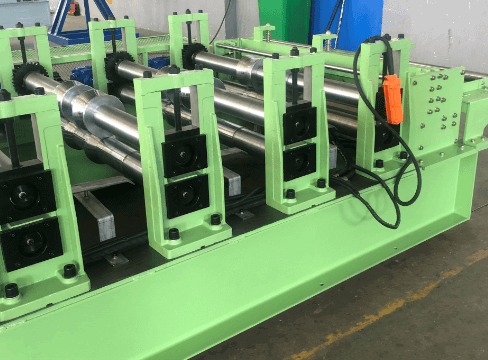

- It uses the molding frame of thickness 45mm as the main frame.

- It used the gearbox as transmission for small noise when working and fast speed.

- When working, its speed can reach 35 meter per minutes.

- It has remotor by which you can control the machine like the cellphone. Stop, run and fast or slow.

- As the whole frame, we use the 400H beam, the machine is durable, it can use more 10 years.

- As it use separated molding rolling, the metal sheet shape will be more beatuful.

- The power can be give more smoohly when working by gearbox.

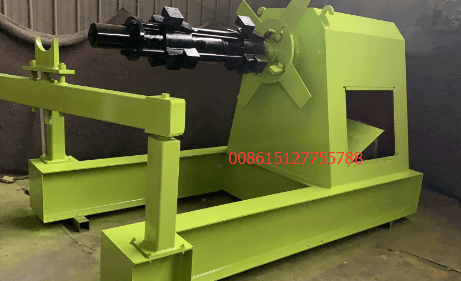

Gearbox transmission metal roofing sheet forming machine for Algeria machine pictures for your reference:

Gearbox transmission metal roofing sheet forming machine for Algeria parameters for your reference:

|

No. |

Main parameter |

|

|

1 |

Length of the main part | 11500 х 1650 х 1450 mm |

|

2 |

Weight of main part | 10 Ton |

|

3 |

Voltage | 380 V/ 50 HZ 3 Phase (as customer’s request) |

|

4 |

Roller fixer | Middle plate welded |

|

5 |

Frame | 400 H steel welded |

|

6 |

Frame thickness | 22mm thicker to be very strong |

|

7 |

Drive mode | Gearbox |

|

8 |

Material of rollers | 45# steel, surface hard chromium plating. |

|

9 |

Material of shafts | 45# steel |

|

10 |

Diameter of shafts | Φ 105 mm |

|

11 |

Number of rollers | 22 rollers |

|

14 |

Main power | 15 kw=7.5kw by two motors |

Why choose Gearbox transmission metal roofing sheet forming machine for Algeria style machine:

- HIGH DUTY STRUCTURE

The sturcture we use for this machine has the higher duty mechanical behavior;

Molding frame type, Europe strandard;

- ROLLERS

The rollers processing by twice CNC machining and hard chromed, HRC 58-62;

Shaft diameter is 76mm for standard;

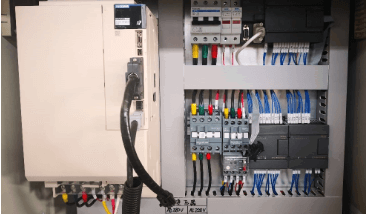

- FAMOUS BRAND PLC

1. PLC controller — Siemens

2. Transducer — Yaskawa

3. Encoder — KOYO

4. Other electronic component- Schneider

4. AUTO STACKER (optional)

4/6/8/10/12 meters long for choice;

Single layer and double layer;

Max stacking weight is about 4 tons;

4. Hydrraulic decoiler (optional)

4/6/8/10/12 Ton for choice;

Single layer and double layer;

For more information of this machine, please conact us at any time.