Keywords:

Interchangeable c/z purlin rolls forming machine, C purline machine, Z purline machine

Description:

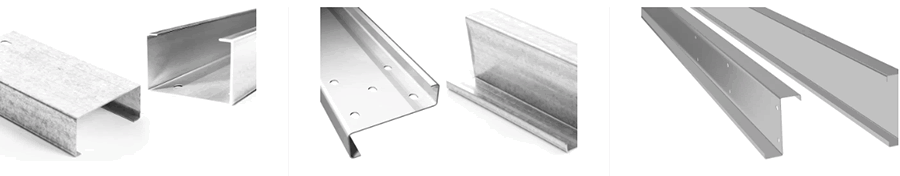

Interchangeable C/Z purlin rolls forming machine is designed to produce the C purline machine, Z purline machine in batch fully automtically.

Interchangeable c/z purlin rolls forming machine

Interchangeable c/z purlin roll forming machine manufactures both Cee & Zed shaped section channels with shapes and sizes quick changed by PLC control within the thickness of 3.0mm from 1.5mm and the bottom sizes could be from 50 to 300mm.

Here use some brief words to descrip the Interchangeable C/Z purlin rolls forming machine. In some degree, we call it as semi-automatic C/Z purlin roll forming machines, even if the changing time is greatly improved, from C to Z could be controlled within 5 minutes but the cutter adjustmnet need manual work.

However, this machine can make both C and Z shaped section channels. People still need two machines for the manufacturing of C and Z steel purlins. Investment on two roll forming machines (one Cee shaped section channel roll forming machine and one Zed shaped section channel roll forming machine) is not ideal solution to contractors or distributiors. As a result, our genuis roll forming engineers have pictured out a new type roll forming machine image in their mind. One machine can make all sizes C channel and Z channel; the punching station can be made as many as you need.

Zhongtuo C/Z purlin interchangeable roll forming machine has been designed to produce both C and Z steel purlins with any sizes available. The profile change including cutting dies for C to Z takes at most 30 minutes (just clutches taken out, a 180° turning on some rolling tools and clutches inserted in) and size change needs at most 5 minutes (just input the required distance through the touch screen on PLC control cabinet ). So much efficiency has been improved by this quick-change c/z steel purlin roll forming machine.

Technical Parameters of Interchangeable C/Z purlin roll forming machine:

Cutting tools adjustable for any sizes of C and Z purlins

- Raw material: Q235 Galvanized steel coil or Cold rolled steel;

- Thickness of Material:1.5—3.2mm;

- Yield strength of raw materials: 235MPA-345MPA;

- Coil Weight: 5 Tons;

- Diameter of Leveling Roller: 90mm;

- Material Width: 300-580mm;

- Feeding guide: 2 pairs slide wheels for adjusting left hand right;

- 2 Pairs pinch rollers: one in each side of leveler;

- 7-Roller Leveler: 3 rollers up and 4 rollers down with no power;

- Forming speed: 0-15m/min(not including punching and cutting);

- Forming steps: 18 stations;

- Diameter of Shafts: 70mm;

- Material of Roller: high quality GCR15 bearing steel;

- Driven: Hydraulic driven type;

- The Max punching thickness: 3.2mm;

- Hydraulic puning & cutting: Stop to punch and cut;

- Materials of Punching Molds: Cr12MoV steel with quench treatment;

- Material of Cutting Blades:Cr12 steel;

- Hydraulic Power: 30KW;

- Hydraulic Cutting:Automatically cutting according to the length and quantities the clients set on the touch screen

- Tolerance of cutting length:+/-2mm

- PLC Control Box: 700mmx1000mmx300mm

- Control System: PLC, inverter and HMI touch screen and Omron encoder

- Voltage: customize

Comparison: manual C & Z machine, semi automatic C & Z machine.

Options A: manual C & Z machine

Traditional c/z purlin can make many section channels of different sizes (standard: 6 different sizes varied from 80-300mm web sizes,50-100mm flange sizes,15-20mm leg sizes), but it needs manual changing and each size changing will take at least 2 hours, as a result, traditional c/z steel purlin roll forming machines don’t work so much efficiently.

Option B: semi automatic C & Z machine

Different with other type CZ purline, ours can finish shape from C to Z can be finished within 5 minute. While on a other design of sem-automatic machine, operators move the respective sub-frames to adjust for different sizes of web heights or flanges.