Square downpipe rain pipe rolling forming machine

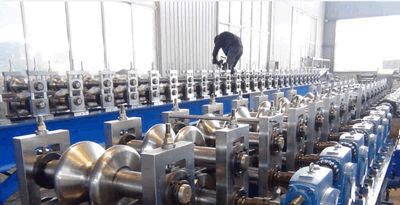

Zhongtuo downspout pipe making machine could be used to make downspout pipes in a higher speed and good quality by 16 years in this area. For this machine, we take guide column frame style to make machine for making sure machine working speed and steady. And for the transmission, we will use gearbox with chain. The machine will be totally same as the following pictures shows.

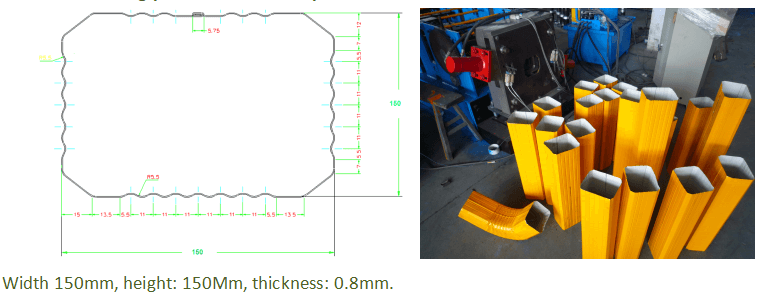

Customer drawing profile and finished product:

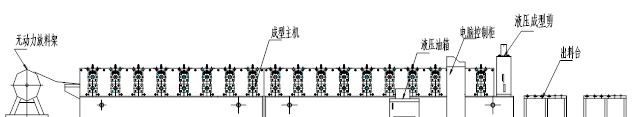

Working process of the downspout roll forming machine:

Decoiler —-feeding —-roll forming—-press of the mould —-shearing —-formed products

Main elements of the downspout roll forming machine:

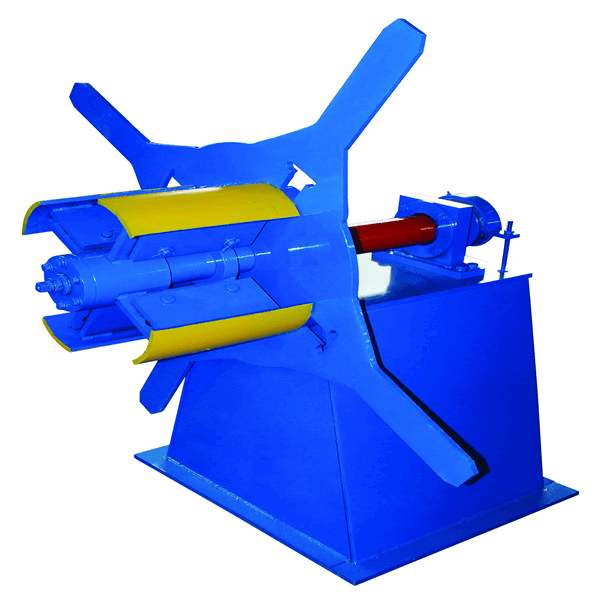

Decoiler

- Usage:passive feeding,manual tension bridle. It will be used for supporting the coil.

- Capacity:3T

Leveling system:

Usage: when coil input, leveling system will level it to make it clean and straight as from coil, it will be a little curve. Curving will affect the pipe making accuracy.

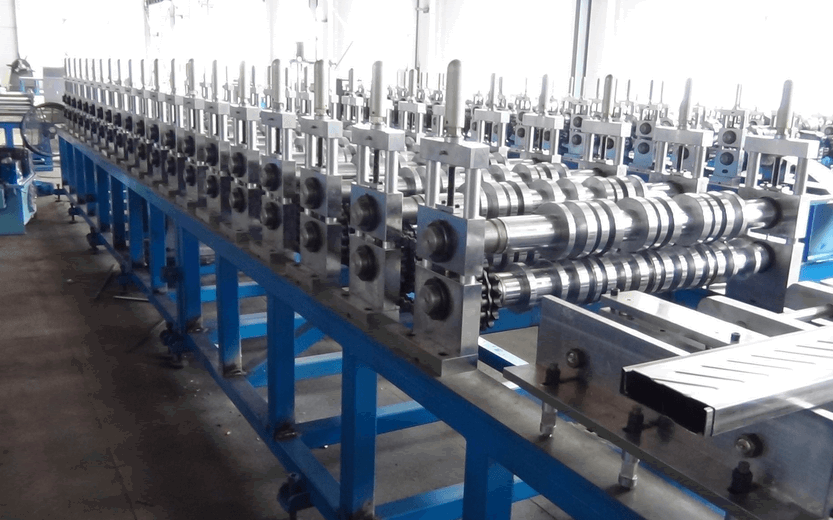

Main roll forming system of downspout roll forming machine:

The machine was composed by the following elements: passive decoiler, one set of main forming machine, one set of hydraulic shearing station, one box of computer control station, one hydraulic oil box, two set of receiving area, one set of bending station.

| Item name | Parameters |

| Power | 5.5kw |

| No. of station rollers | 24 rollers and horizontal roller and a series of vertical roll |

| Transmission | chain |

| Forming speed | 8-10m/min |

| Supported material | 0.4-0.8mm color steel sheet or GL, GI and others |

| Single sided coating | 0.05mm |

| Hydraulic station power | 5.5kw |

| Error | ±2mm |

| Main machine size | 8000 mm×1250 mm×1500 mm |

| Control style | the high voltage control |

| The maximum bending | 900 |

| Function | combination of bending and lock function |

| Elbow Bending speed | 5m/ min |

| Power of main motor | 2.2kw |

| Material of shearing | Cr12 |

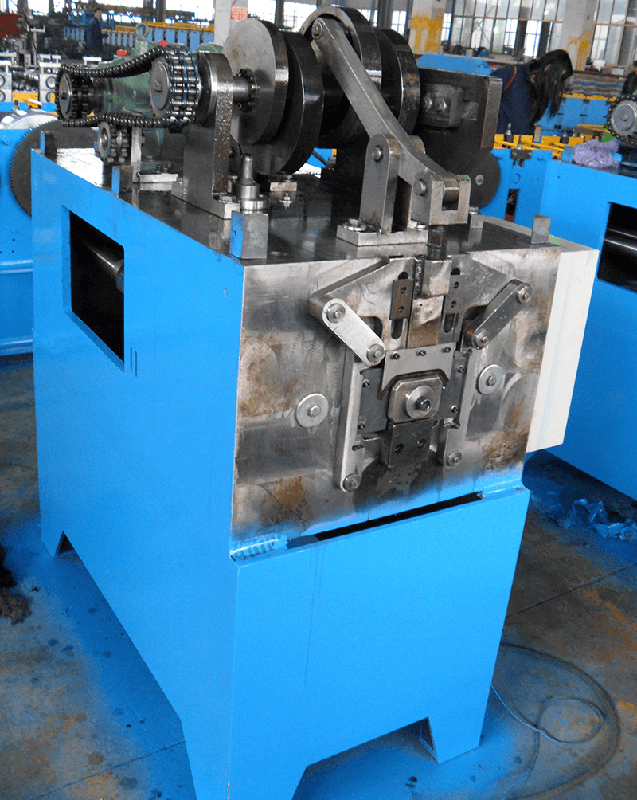

Downspout Pipe Bending Machine

Brief introduction:

For the straight downspout pipe and elbow pipe cannot be made by one machine. When you need to make the elbow, you need to use this pipe bending machine. The following are some information for your reference:

- Control style:the high voltage control

- Supported material: Colored steel panel with thickness of 0.8mm