Title: Sandwich panel making machine, wall and roof panel roll forming machine line, Discontinuous PU sandwich panel machine

Keywords: Sandwich panel making machine, wall and roof panel roll forming machine line,

Description: PU sandwich panel machine

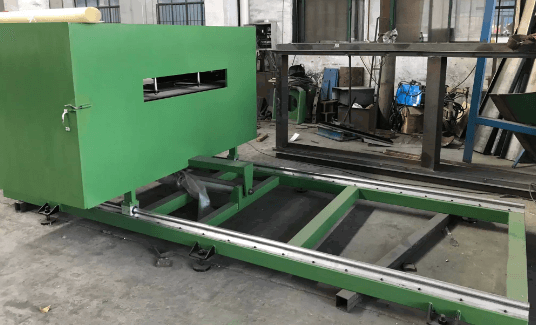

Discontinuous PU sandwich panel machine

1. Made by Korean Technology and designer

2. ISO CE certificate

3. Competitive price

4. Thoughtful sales service

Fully Automatic Sandwich panel making machine, wall and roof panel roll forming machine line, Discontinuous PU sandwich panel machine allows you to make sandwich panel in batch and fully automatic.

It-has-including unwinding, before cutting, film, beading / molding, rock wool and spray delivery,Edge foam, continuous curing, cutting and other functions, high degree of automation, stable performance.Edge polyurethane foam systems, automatic feeding system, to ensure that the raw material requirements in full accordance with the ratio of mixing, spray evenly; using a reliable foam technology to ensure uniform sheet foam, dense, sheet closely connected.The production line is equipped with automaticcontrol system, userfriendly interface for easy operation, monitoring, advanced computer control, easy to adjust the entire line of argument, effectively ensure the production line stable and efficient operation.

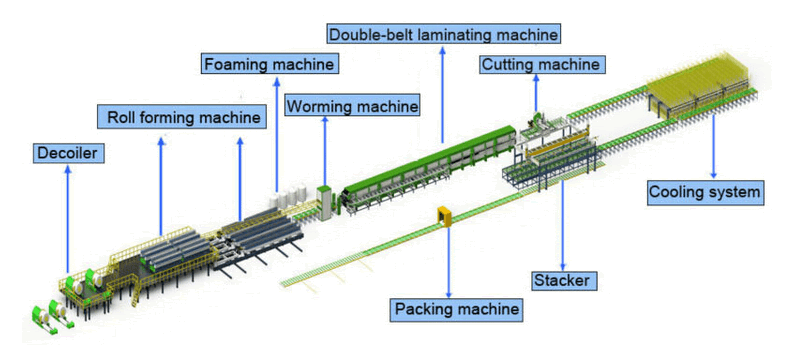

Discontinuous PU sandwich panel machine working flow:

Sandwich Panel for EPS, PU and rockwood making machine production Process:

(The upper)Dncoiler —Cutting —Film—Beading—Roll forming \ (Lower part)Uncoiler — Cutting →Film→Beading→Roll forming /—Rock wool delivery—Glue—Sealing side foam— laminating machine with Foam,Solidify,Roll forming—Cutting —Run-out table

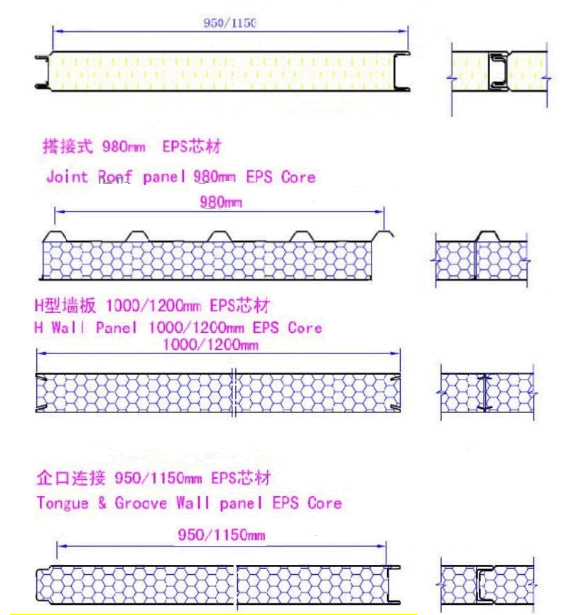

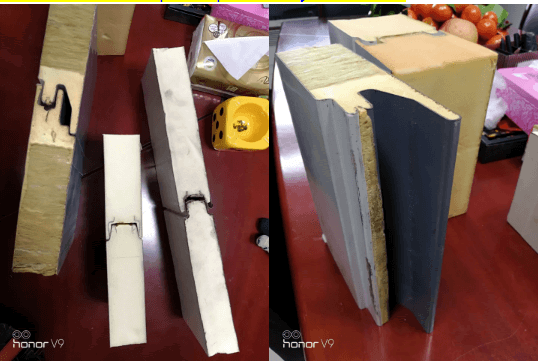

PU Panel, EPS panel, Rock wood panel ects, sandwich panel drawing profiles showing:

PU Sandwich Panel production line is specially designed for producing Z-lock PU sandwich panel continuously.

The facing material of this panel can be PPGI, Aluminum foil, PVC sheets, etc and the core materials can be Polyurethane, Mineral Wool, Glass Wool, PIR, Phenolic or EPS.Panel shape can be tailor-made according to customer’s detailed requirements.

Here are some finished product pictures for your reference:

Fully Automatic Sandwich Panel for EPS, PU and rockwood making machine more details pictures for your reference:

ain parameters:

Speed: 0~8m/min, frequency control.

Total power: about 200 KW

Production line length: more than 100 m

Workshop required: about 120m x 18mx 5.5m

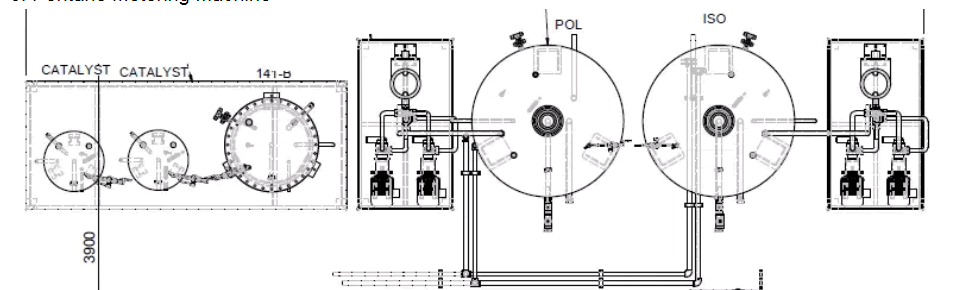

PU injection machine: two or four components, original from Italy

Double belt length: 24m or tailor-made

| Speed | 0~8m/min, frequency control |

| Total power | about 200 KW |

| Production line length | more than 100 m |

| Workshop required | about 120m x 18m x 5.5m |

| PU injection machine | two or four components |

| Double belt length | 24m or tailor-made |